This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Filling and capping monoblock PHARMLINE

- Home

- Filling and capping monoblock PHARMLINE

FILLING AND CAPPING MONOBLOCK FOR AMPOULES AND VIALS PHARMLINE

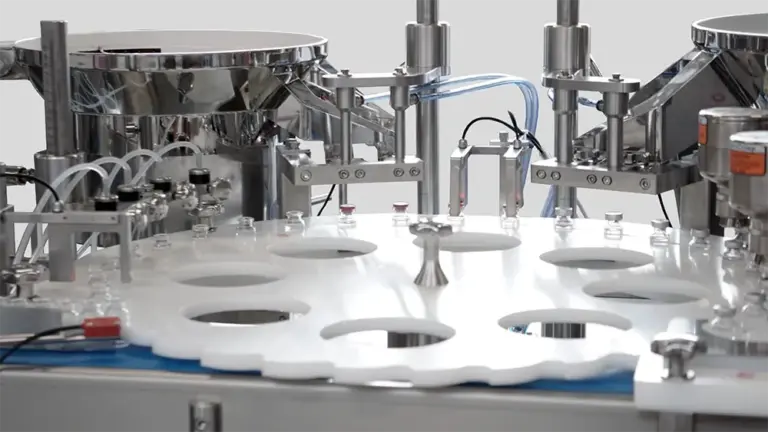

The PHARMLINE Filling and capping monoblock machine is used to fill ampoules, medical glass vials, bottles and jars with screw, pressure and twist-off caps. The lyophilization caps can also be crimped.

These filling and closure monoblocks are mainly used in the pharmaceutical and cosmetics industries. At the same time, they have a permanent place in food companies wherever the space available for setting up a filling line with an independent filling and capping machine is limited. The monoblocks are mainly used for filling smaller volumes.

The filling and capping monoblocks are supplied in two versions: Pharmline 1 with a capacity of up to 2 600 bottles/ampoules per hour and Pharmline 2 with a capacity of up to 5 200 bottles/ampoules per hour.

In the pharmaceutical industry, peristaltic pumps and possibly flow meters are mainly used for dosing, while lobe pumps are used in the food industry and gear pumps in the cosmetics industry.

For the supply of caps are mainly used vibratory erectors, although sometimes can be applied also rotating feeders.

The capping head is operated by a servomotor with a capping torque that can be precisely adjusted via the control panel.

Monoblocks for the pharmaceutical industry are produced in accordance with GMP and FDA requirements; the delivery also includes optional verification documentation and a complex assurance system.

PROCESS DESCRIPTION

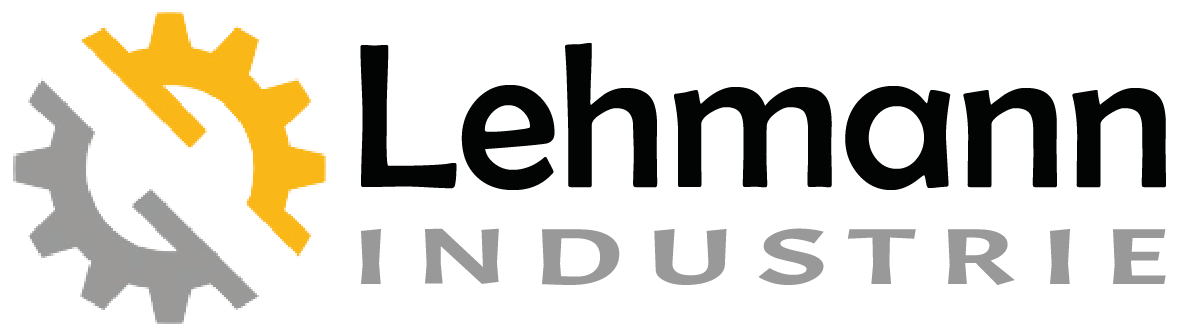

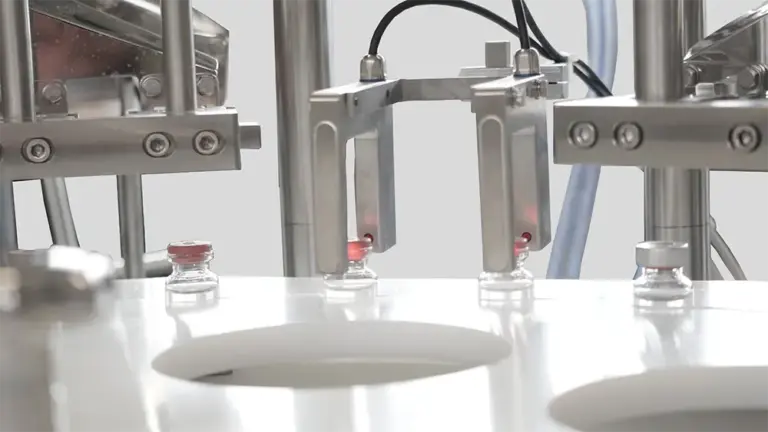

Empty vials (or other containers) are transported by infeed conveyor to the starwheel. At the entrance vial presence sensor is located. The first station is filling. Machine can be equipped with 1 to 6 filling positions. For filling peristaltic pumps are used. Other types of dosing system are also available (Lobe pumps, flowmeters etc.).

Next operation after filling is capping. In standard execution, the machine is equipped with a capping device for screw caps that consists of caps feeder, caps chute, pick and place device and capping head. This capping device can be replaced closing unit for press-on caps by crimping or other system. Additional capping unit for application of droppers, dozers or rubber stoppers can be added. Filled and closed containers leave the machine on outfeed conveyor.