ANFD Working Principle

- Home

- ANFD Working Principle

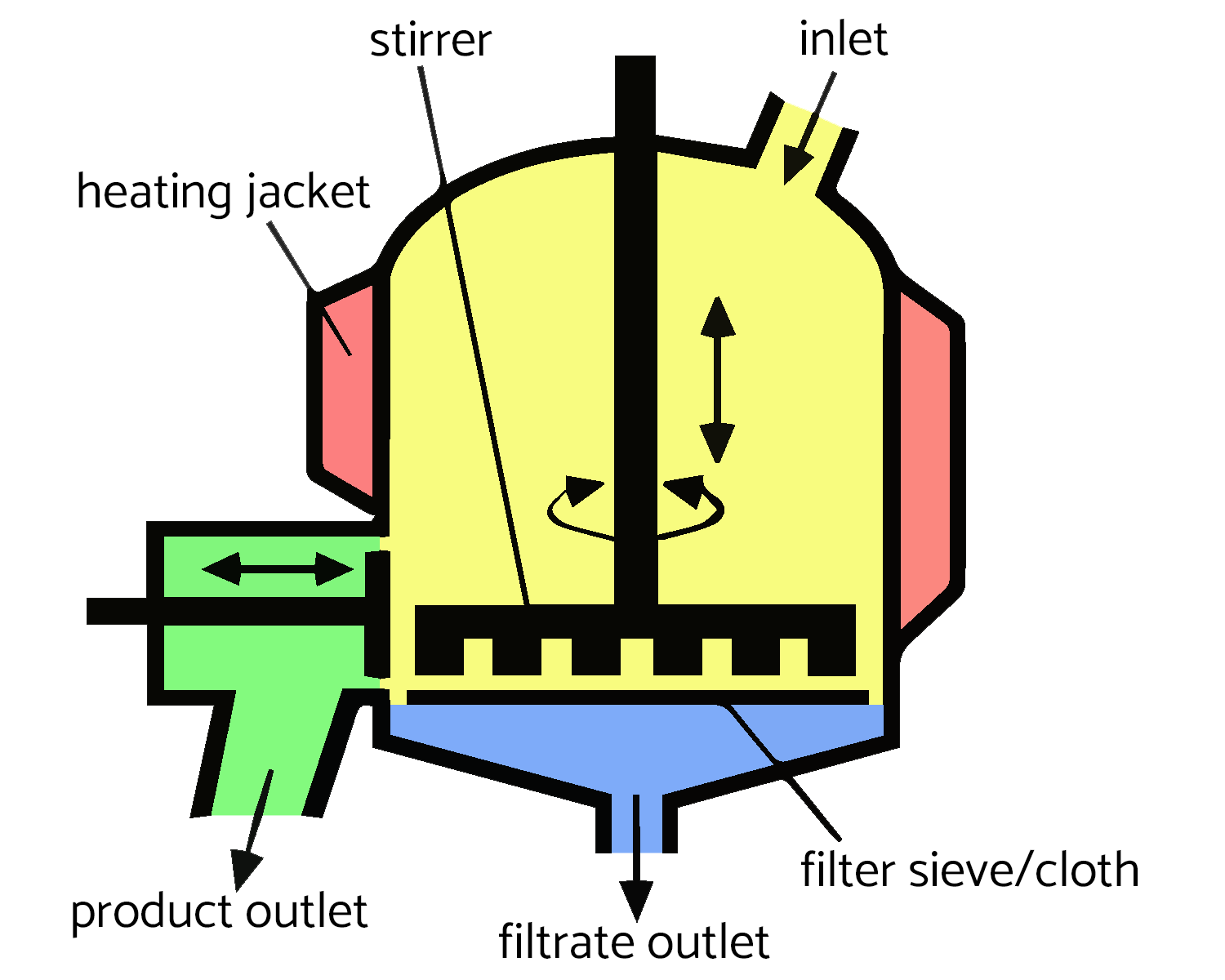

PRINCIPLE SCHEMATIC PICTURE OF THE AGITATED NUTSCHE FILTER DRYER (ANFD)

- the yellow space is the working space where the material/product is processed

- the blue space is located under the filtering mesh (cloth), through which the suspension is filtered and where the filtrate – liquid leaves the ANFD

- the red space is the heating jacket that warms up the material/product. In case of a special application is this feature sometimes not necessary, thus not supplied

- the green space is the space through which the dry material or crystals exits the ANFD

- the stirrer has a special J-form shape due to the fact that it performs a different function in the reverse movement than in the clockwise direction of rotation

- the filter mesh (cloth) has the porosity you choose according to the size of the crystals or other particles in the suspension

Note: this basic scheme can be variously combined and supplemented, for example, by heating of the infeed raw materials, the contactless emptying system, contactless filling into containers, etc.

WORKING PRINCIPLE OF THE AGITATED NUTSCHE FILTER DRYER (ANFD)

ANFD usually works in 4 basic modes:

1. Mixing

used in the filling phase for a basic mixing, for the material homogenization, or for crystallization.

- According to the purpose, the stirrer rotational speed varies (for example in case of crystallization, the speed is very low), the stirrer rotates in the clockwise direction, and in addition, the stirrer can move up and down for the best possible mixing.

- This cycle step can run at normal atmospheric pressure or under pressure.

- The filtrate outlet and the product outlet are closed, the inlet can be opened or closed depending on the technological process

2. Washing the product

used to clean the product by washing & rinsing with a suitable liquid (this process is usually repeated several times esp. when it deals with crystals)

- The stirrer rotates very slowly in the clockwise direction and very slowly alternately up and down.

- Working under pressure.

- product outlet is closed, the filtrate outlet and the “water” inlet can be opened.

3. Filtration / drying & heating

used in the finished product/crystal separation phase (for crystals to be preserved, this procedure is not applied)

- The stirrer rotates very slowly clockwise and very slowly down, thereby mechanically forcing water out of the suspension and at the same time the product is heated and dried.

- Working under pressure.

- product outlet and the inlet are closed, the filtrate outlet can be opened

4. Discharging

used in the finished product/crystal phase

- The stirrer rotates very slowly counterclockwise (reverse) and very slowly down, thereby pushing the product or crystals to the wall and into the green product outlet,

- If the dried product has hardened, the sharp edge of the agitator cuts it off, allowing the product to be rolled up through the green side outlet.

- This cycle step runs at normal atmospheric pressure.

- the filtrate outlet and the product outlet are opened, the inlet can be closed

DOWNLOAD WORKING PRINCIPLE OF THE AGITATED NUTSCHE FILTER DRYER AS PDF

Herunterladen