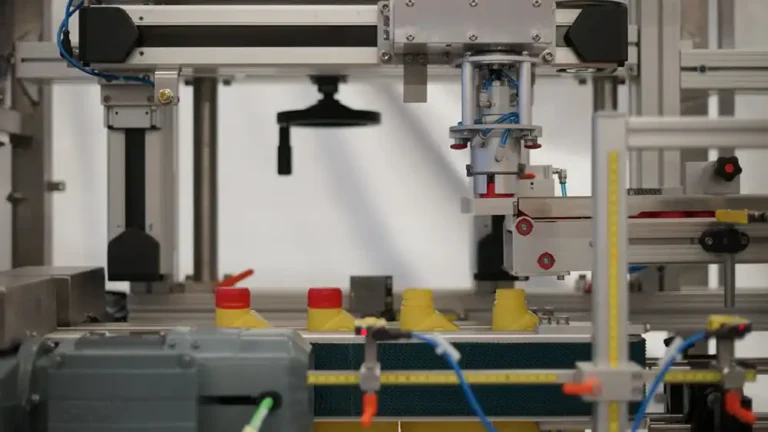

Capping machine with movable head

- Home

- Capping machine with movable head

CAPLINE DYNAMIC

Capline Dynamic is fully automatic continuous capping machine. The containers are closed while moving in order to avoid possible splashing of product. Thanks to linear design of the machine no format parts for different sizes of containers are needed.

KEY FEATURES

- Stainless steel machine frame with height adjustable legs

- Motorized stainless steel conveyor with adjustable speed

- Adjustable side belts to stabilize and guide the bottle while capping

- Rotary caps orientator on the top of the machine

- Cap chute with sensor for cap presence check

- Pick and Place device

- Capping unit with movable axes that allows capping of the bottle while moving

- Sensor to detect bottle presence in the capping area

- Encoder system controlling bottle and canister speed

- Sensor to detect full downstream conveyor

- Control panel with touch screen

- Safety guards

PROCESS DESCRIPTION

The container enters the machine on the conveyor belt. Inside the machine the container is stabilized and guided by two side belts. Caps are oriented in vertical caps feeder/orientator or in rotary caps orientator.

Oriented caps pass through the caps chute to the pickup point, where they are taken by dynamic servodriven capping head. The capping head follows the movement of the containers and tightens the caps on requested torque during the container transport. Closed bottles leave the machine on downstream conveyor.