Here you will find videos and photos of the commissioning of the Tubeline tube filling and sealing machine for metal and plastic tubes at WP Tiernahrung GmbH in Pöttelsdorf, Austria.

Here you will find videos and photos of the commissioning of the Tubeline tube filling and sealing machine for metal and plastic tubes at WP Tiernahrung GmbH in Pöttelsdorf, Austria.

We have delivered for the German manufacturer of flavors and fragrances Bell Flavors & Fragrances GmbH a Labeling machine SYSTEM 1 for labeling of 1,25 L round tin cans.

At the end of 2024, UNIKO, a member of the ALBERTINA Machinery s.r.o. group, delivered the Tube Filling and Sealing Machine type UP 175 to their loyal customer Pharma C-Food Sp. z o.o. from Poland.

Commissioning of the Tube Filling and Sealing Machine type UP 30P for plastic tubes went well.

Upgrade of the semi-automatic tube filler UP30 to a fully automatic version UP175P. As with the UP30, the UP175 is based on a very proven robust construction based on cams and mechanical end stops. It is basically an indestructible machine!

We thank the company Reincke Naturfarben GmbH for their trust in us and hope this machine is not the last one.

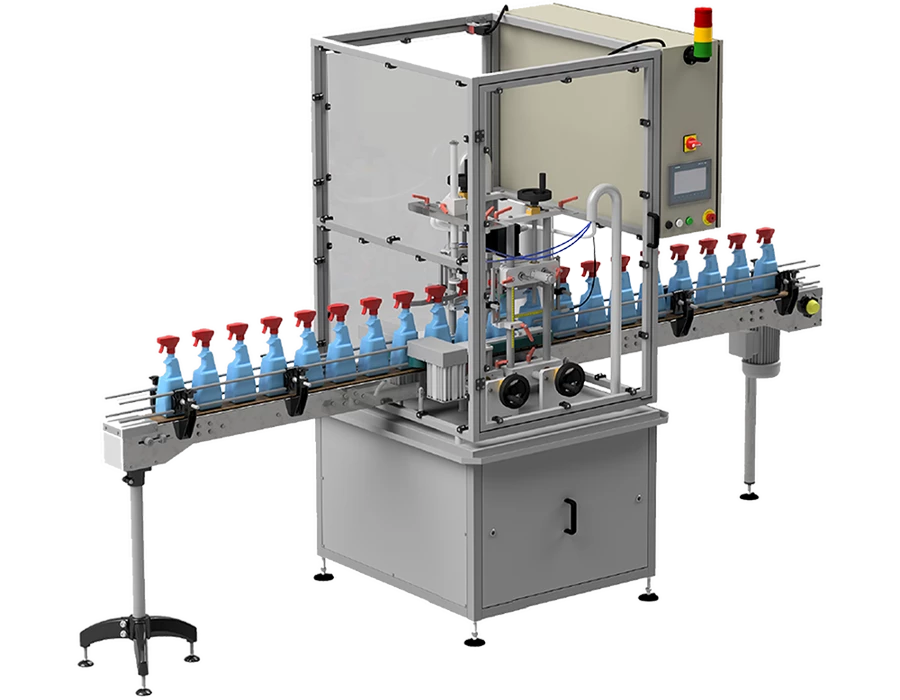

The linear capping machine model Capline PMP for immediate delivery with a very attractive stock price!

Universally applicable machine for capping spray heads, screw caps, pump caps or press-on caps! Caps are applied manually, although the capping process is fully automatic.

Offer price guarantee while stocks last!

Adaptation to your process and commissioning are naturally included in our scope of delivery.

In the last year we have noticed a huge sales success with the tube filler Tubeline, due to balanced cost/performance ratio and a great proportion of the layout against the productional output. It’s thanks to the concept of the rotary table, but as we know, this design has its capacity limitations.

Therefore, company ALBERTINA designed, tested, and put on the market a new tube filling & sealing machine Tubeline 6000 HS based on the servo-driven indexing oval table, allowing to increase the machine capacity to double. What’s more, imagine that by doubling the filling and closing stations we increase the machine output by another double!

As with the previous type, the machine is designed to fill and close plastic, laminate, and metal tubes, the change-over of the equipment to metal tubes does not take long.

Tube filling can be realized from the tube magazine, which this time can hold the content of up to 3 cartons or both filling and removal of tubes can be performed by a robot. See more detailed information about the machine here: Tube Filling and Sealing Machine Tubeline 6000 HS | LEHMANN INDUSTRIE (lehmann-industrie.de)

In today’s manufacturing environment, efficiency and precision are paramount. Businesses are constantly seeking innovative solutions to streamline their production processes and reduce costs while ensuring product quality. One such groundbreaking solution is the Capline Dynamic, a fully automatic continuous capping machine that revolutionizes the capping process.

This article aims to shed light on the remarkable features and benefits of the Capline Dynamic, showcasing its ability to optimize operations and elevate productivity.

Unleashing the Power of Capline Dynamic:

The Capline Dynamic sets itself apart by combining cutting-edge technology with a user-centric design. Its linear configuration eliminates the need for format parts, enabling seamless adaptation to different container sizes.

Let’s delve into the machine’s exceptional features that make it a game-changer in the industry:

Process Description:

The operational excellence of the Capline Dynamic is exemplified by its streamlined capping process. As the container enters the machine on the conveyor belt, it is stabilized and guided by adjustable side belts. The caps, meticulously oriented through a vertical or rotary caps orientator, seamlessly transition through the cap chute to the pickup point. Dynamic servodriven capping heads then secure the caps onto the moving containers, ensuring precise torque application. Finally, closed bottles gracefully exit the machine on the downstream conveyor, ready for the next phase of production.

We thank the Czech company HERBAI for enabling a reference visit to their factory for our German customers.

We could have seen the newly installed Tube Filling and Sealing Machine Tubeline with an outfeed conveyor and turntable and a Filling & capping monoblock COMPACT for small ampoules.

At the end of May we visited our customer in beautiful Austria, where we delivered and commissioned our Automatic tube filler TUBELINE for filling and closing plastic tubes with wasabi paste. Thanks to the presetting of the machine during the FAT tests in our production facility, where our customer was also present, commissioning was quick and uncomplicated.

We thank to our client for his trust, wishing him a lot of commercial success with his new product and look forward to further cooperation.

We attended the No. 1 international trade and packing fair interpack trade fair in Düsseldorf, Germany, at the stand of our business partner & supplier – company Albertina, a traditional producer of filling, capping and labelling machines and complete filling lines. Albertina delivers machines and filling lines with a capacity of 500–12,000 bottles per hour.