Lab and Pilot Pressure Reactors

- Home

- Lab and Pilot Pressure Reactors

LAB AND PILOT PRESSURE REACTORS

Company VSK designs and manufactures custom made agitated reactors and autoclaves, tailored to every even very specific demand coming from fine chemical, pharmaceutical and food processing industry. The systems are designed for operation at a wide range of pressures and temperatures, with applications ranging from laboratory and pilot plant to large chemical plants.

Due to the wide variety of sizes available (in vessel volumes from 350 ml to 6 m³), we have divided them into laboratory & pilot plant and industrial systems (from 50-liter vessel volume). However, it is by no means specified from which volume it is no longer a pilot plant but an industrial equipment. Simply contact us with your specific requirements!

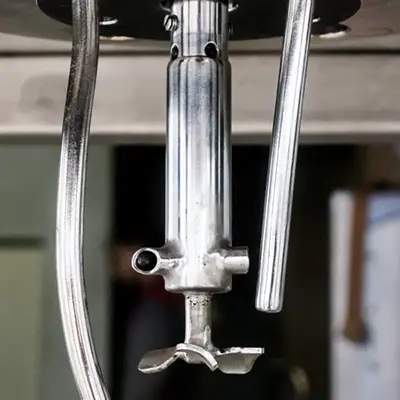

Anchor, blade and hydrogenation stirrers

Hydrogenation stirrer

KEY FEATURES

- Vessel:

- volumes: from 0,35 to 50 liters

- pressure: -1 to 200 bar

- temperatures -20 °C to +250 (400) °C

- heating jacket or direct electric heating

- lateral sight glasses

- lifting/lowering the reactor

- drain valve

- Stirrer drive:

- direct electric motor or via belt transmission

- speed 0 – 2000 rpm stepless adjustable

- magnetic coupling with cooling

- Cover plate:

- 6 openings NPT ¼

- Swagelok® fittings

- manometer, Pt-100,

- bursting disc

- Stirrers:

- anchor, blade stirrer, propeller, turbine, impeller, helicoid, hydrogenation

DESIGN

- Custom made design! (no catalog massive production)

- Designed in accordance with ATEX 2014/34/EU for Zone 0 / Zone 1 / Zone 2

- Pressure vessel according to PED 2014/68/EU and EN 13445

- CE certificate and marking according to 2006/42/EU

- Optional electrochemical polishing of the inner surface

MATERIAL OF CONSTRUCTION

- Stainless steel (AISI 316Ti, AISI 316, AISI 304)

- Nickel alloys (Hastelloy® C22, Hastelloy® C276, Hastelloy® C2000)

- Titanium

- Coating (PFA RubyRed, Halar E-CTFE,…)

FEW EXAMPLES OF CUSTOM-MADE LAB AND PILOT PRESSURE REACTORS

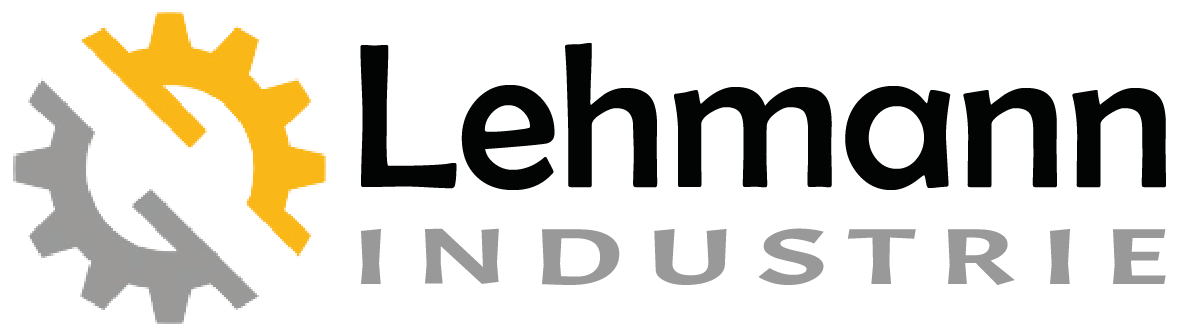

PRESSURE REACTOR 3 L, 25 BAR

- pressure -1 to 25 bar(g)

- temperature 250°C

- heated by electric heater (1 kW)

- easy tightening of main flange by chain clamp

- magnetic coupling Büchi bmd300 (max. 3Nm)

- 3 types of replaceable stirrers – 2-blade, 3-blade and turbine

- lifting of vessel (manually operated by hand crank)

- trolley for vessel with option of tipping

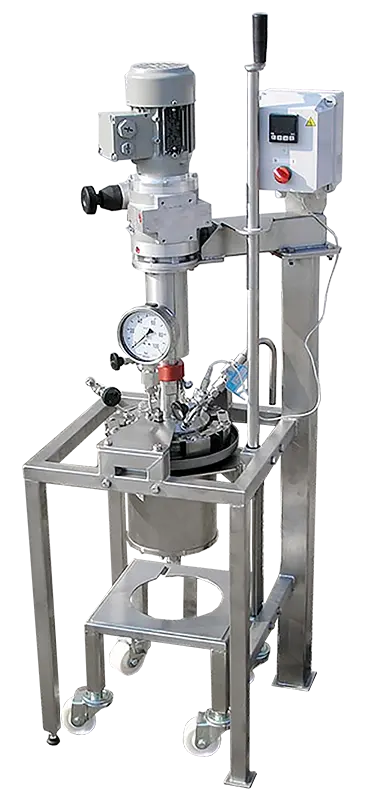

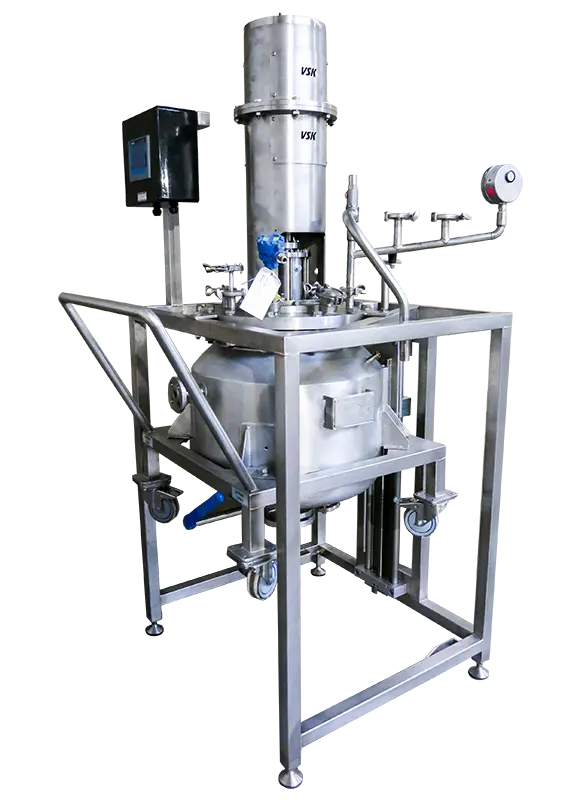

HYDROGENATION REACTOR 5 L, 90 BAR

- max. temperature 150°C, max. pressure 90 barg

- magnetic drive Büchiglasuster

- hydrogenation 4 bladed stirrer

- electric drive 250 W, frequency drive (speed 400 – 2000 rpm)

- material stainless steel 1.4571

- supporting rack with vessel lifting mechanism

- heating oil circulatory unit 3,5 kW with pump

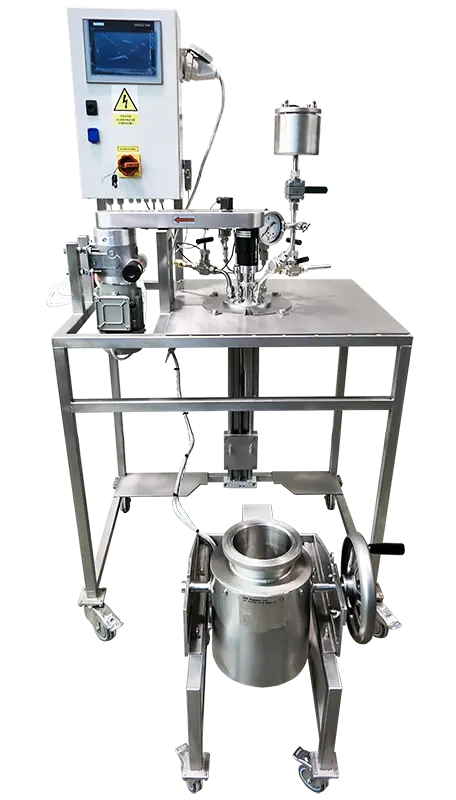

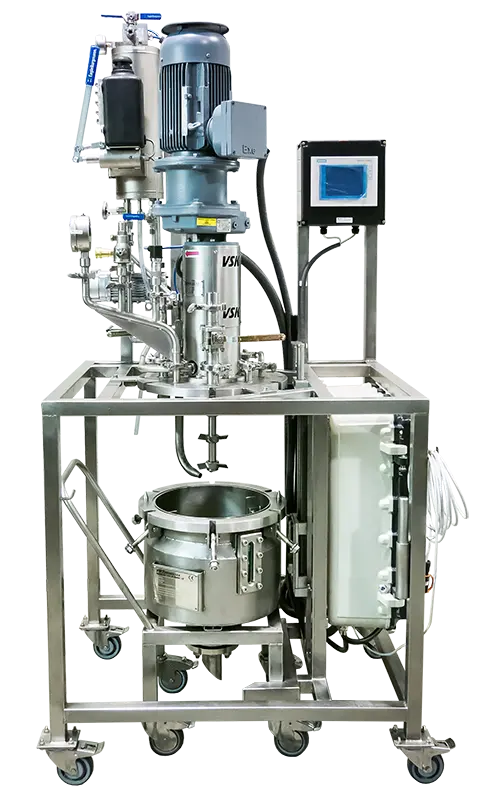

PRESSURE REACTOR 50 L, 6 BARG

- operating temperature -20 to 160°C

- operating pressure -1 to 6 barg

- stainless steel AISI 316, surface grinded Ra < 0.8 μm

- heating jacket (steam)

- spiral mixer, electric drive 0.75 kW

- speed range 150 to 400 rpm, frequency invertor

- double mechanic sealing with barrier fluid and cooling flange

- vessel lifting mechanism (manually operated by hand crank)

- PLC control panel with touch screen LCD