Bottle unscramblers

- Home

- Bottle unscramblers

KEY FEATURES

- wide range of serving containers from small bottles to canisters

- wide range of machine options in terms of performance

- easy format conversion with minimal costs for replacement parts

- secondary orientation of containers and caps

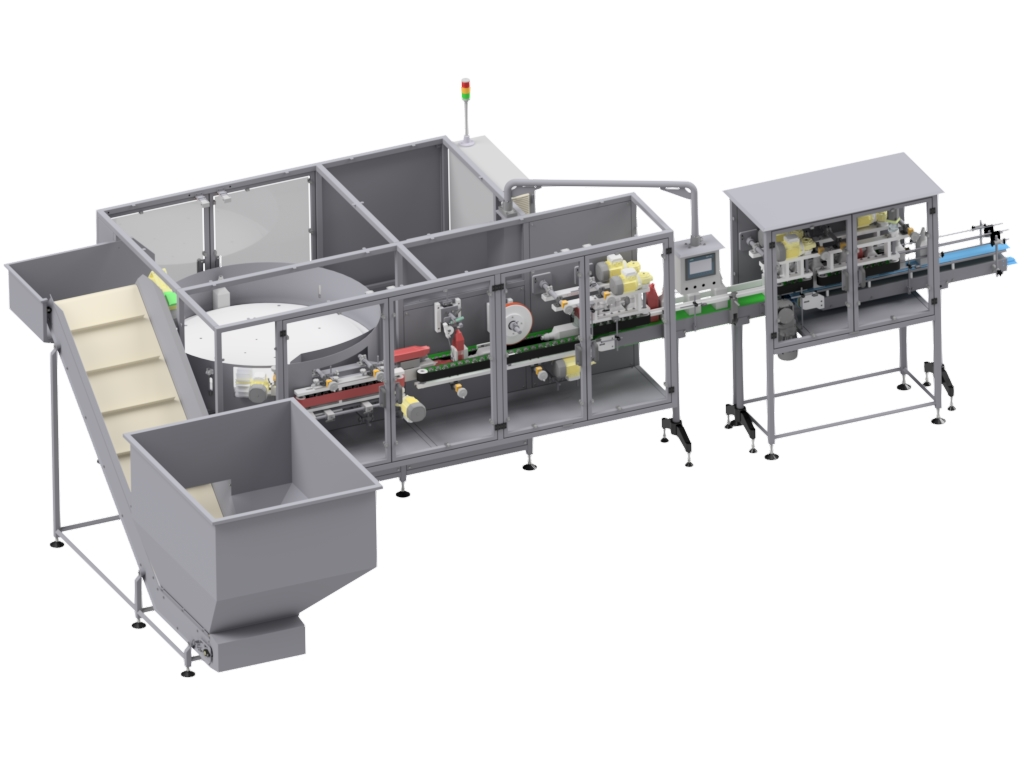

Ansa 800

The small bottle unscramblers are designed for use primarily in pharmaceuticals and cosmetics. They are also used for orientation of bottles for filling E cigarettes, etc. The bottles are emptied into a drum, from which they are moved in a horizontal position to a belt and here they are oriented with the neck in one direction by means of a special mechanical turner. They are then placed in a vertical position by means of a system of side belts and continue along the conveyor to the filling machine.

Ansa 1000-2000

Bottle and canister unscramblers are used wherever bottles and canisters have to be automatically fed onto the conveyor belt of the filling line. Since most containers have their necks positioned off-centre, it is necessary to incorporate a secondary orientation system downstream of the erector, so that the containers are aligned in one direction and conveyed onward to the inlet of the filling machine.

Ansa Viber

Vibrating cap orientation devices and vibrating tracks are mainly used for orientation and transport of caps to the capping unit of the machine. The caps are loaded into the vibrating drum and there they are oriented and guided into the path by means of a helix and a system of air nozzles, and then moved to the capping station. The cap orientation devices are manufactured in 3 sizes with diameters of 600, 400 and 250 mm.