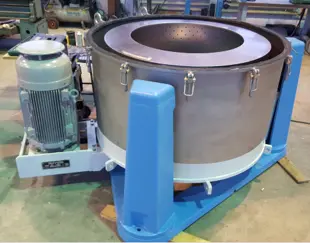

Our company offers maintenance and modernization services of all filtering centrifuge types all well-known manufacturers such as Ferrum, Andritz (Krauss Maffei), Heinkel, Rousselet Robatel and others.

Based on the requirements of the machine operator, we are able to perform tasks ranging from simple performance of periodic maintenance work to upgrading of the machine, including changes in technological and other parameters. We perform these activities on both machine and electric parts. As part of these activities, we can also complete the customer’s documentation with the necessary regulations, instructions, certificates, IQ/OQ, etc.

- Installation of centrifuges on site

- Teaching the operator’s staff

- Maintenance and periodic inspections of centrifuges

- Repairs and modernization

- Fault diagnosis, report and precautions, repair of centrifuges of all manufacturers

- Spare parts of original and own production

- IQ / OQ certification

Due to our own experience with the construction and production of our own SULTRADE centrifuges, we can easily help you to refine or upgrade your centrifuge from any manufacturer. It may be:

- Modernization for operation in the ATEX environment

- Modernization according to GMP standards

- Addition of workspace inertization

- Modification, addition of control system / program

We supply OEM spare parts and our own design and production, fully exchangeable with originals for centrifuges of:

- Ferrum

- Andritz (Krauss Maffei)

- Heinkel

- Rousselet Robatel

- and others