We have recently delivered another Screw Mixer type HV 1000 for the German company M & K Gewürze GmbH.

TECHNICAL DATA:

- Working volume 1000 liters

- All parts inside the vessel / vessel, mixing screw, arm, lid are made of stainless steel 1.4301 (AISI 304)

- The support beam is clad with 1.4301 stainless steel sheet on the underside

- Inner surface Ra1.6 micro-blasted on the outside

- PHARMIX gearbox with belt drive and liquid feed device

- SIEMENS motor 4 kW, 400V, 50 Hz

- Mixing time 150 min

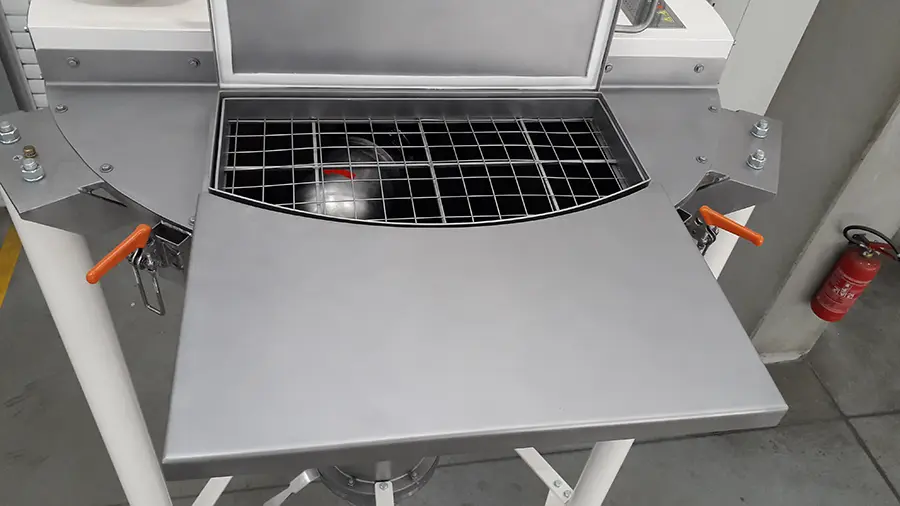

- Filling opening 600 x 325 with lid on gas pressure spring

- Construction material 1.4301, grid with mesh 40 x 40

- connection DN150

- Manually rotatable butterfly outlet

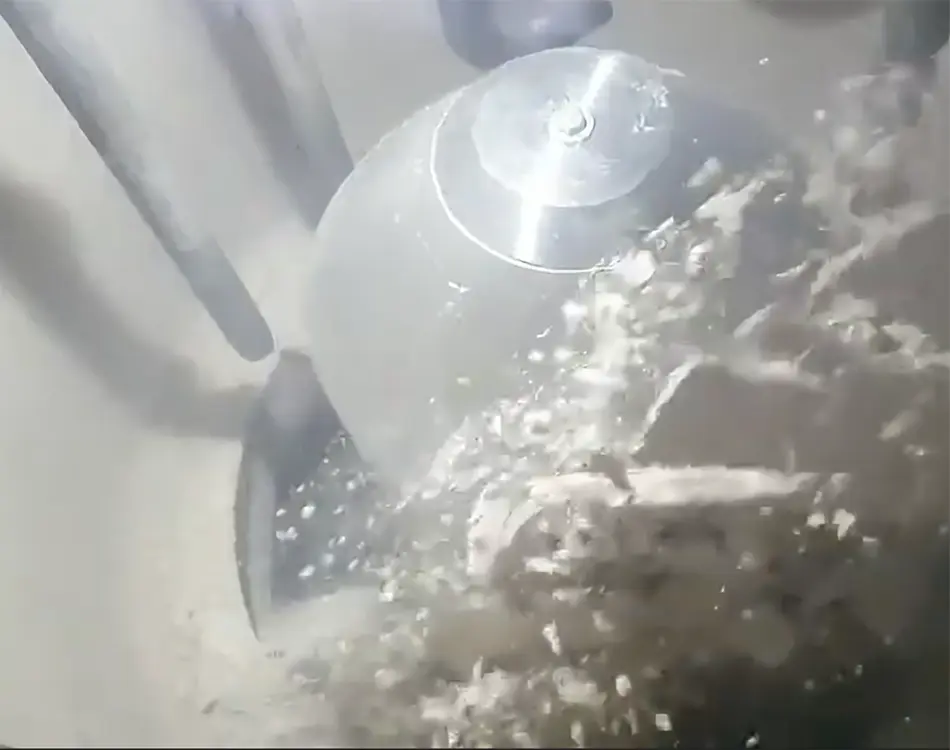

- Lump breaker 3 kW, 400V, 50 Hz

- Inspection door 520 / 500 x 500 with safety switch

- 3 legs made of 1.4301, glass bead blasted

Previous

Next